CONTACT WITH US

Quick Details

- Place of Origin: Taiwan

- Brand Name: Intertech

- Model Number: NCBI-3705

- Shaping Mode: Compression Mould

- Product Material: silicone, lsr

- Product: liquid Silicone rubber Mold & molding Making

- Product Name: liquid Silicone rubber Mold & molding Making

- Quality: RoHS and SGS standard

- Size: According to your drawing

- Structure: According to your drawing

- Color: Can be discussed

- Cavity: Single Cavity or Muti Cavity, based on customer's requirement

- Mold Base: HASCO standard, European standard, World standard

- Mold Material: German and Japan import steel

- Products Certifications: Upon on Customer's requirements, CE / SGS / FDA...are availbale

- Surface Finish: Texture (MT standard), high gloss polishing

Packaging & Delivery

| Packaging Details: | For Parts: bulk or individual pack, upon customer's demands with exported carton box. For Mold: Standard exported wooden box packed, fumigation process (upon required). |

|---|---|

| Delivery Detail: | T1, 20~40 days, parts measurement report (upon required). |

liquid Silicone rubber Mold & molding Making

Product Description

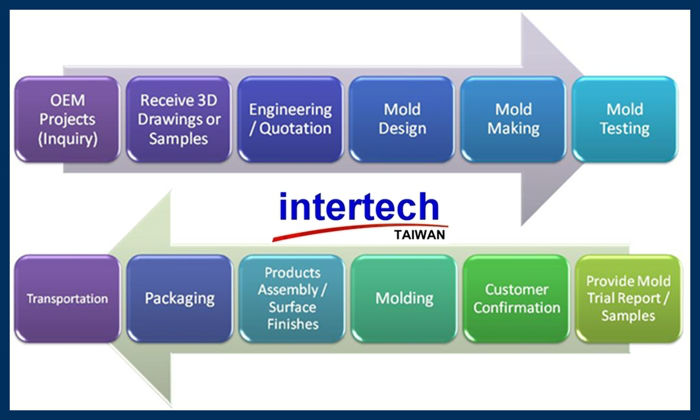

Our Services

Our Professionals:

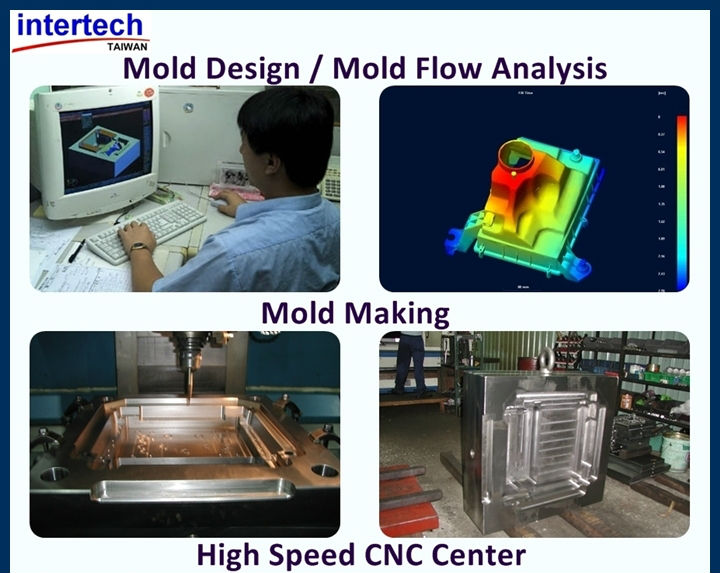

- Use advanced rubber mold equipments to make fine quality rubber mold products for rubber mold clients for decades.

- Mold cavity can be single cavity or multiple cavity, upon customer’s requirements or depend on how many quality will customer need in week / month / year…

- Offer cost-effective rubber mold fabrication services to the manufacture of finished rubber products.

- All of our engineering & manufacturingworks are 100% made in Taiwanwith highest quality performance.

- We manufacturing rubber molded keypads, buttons, gaskets, seals and other components used inhouse wares and automotive, consumer electronics, sporting goods, doors and windows applications and commercial applications.

- We also provide Rubber forming (overmold) services to produce rubber to metal parts.

- This manufacturing process is useful for the production of small quantities of parts.

Company Information

About Us:

In short, Intertech (Taiwan) provides an extensie integrated operational ability from design to production of molds 100% made in Taiwan.

With the performance level in Taiwan, we satisfy our world customers with the best value of mold making workmanship: customer design service; prototyping; mold making; manufacturing process control; reverse engineering; customer molding & assembly...etc.

We manufacture plastic injection molds, die-casting molds, silicone rubber molds, liquid silicone rubber molds, LSR molds, rubber molds, press molds and hot runner molds (MoldMaster, MasterFlow, LKM, Incoe systems...etc).

We are particularly specialized in dealing with undercut molds, unscrewing molds, core pulling structure molds, high gloss polished molds, interchangeable core molds, hot compression molds, 2-component injection molds, and pilot molds for small series production...etc.

To know us more, please visit www.taiwanmoldmaker.com; www.intertech.net.tw

Company Certificate: D&B D-U-N-S® Registered™ Certificate

Exhibition / Tradeshow: EuroMold and TurnTec Exhibiton

Packaging & Shipping

For Parts: bulk or individual pack, upon customer's demands with exported carton box.

For Mold: Standard exported wooden box packed, fumigation process (upon required).

For Mold: Standard exported wooden box packed, fumigation process (upon required).

FAQ

1. Besides molds, do you generate products as well?

Yes, we can make your projects here in our factory, Taiwan for you. But we only make it from making a new mold...then, from above new mold, making parts out of it. We make the production job for our customers in Taiwan. In other words, we do not have any existing mold. In short, we produced customized molds and products but we also provide our customers reverse engineering service.

2. How can I get the quote?

First, we need our customers provide their technical data like 2D, 3D drawings or samples. After receiving your project, our experienced and professional team will start to study and evaluate it. During this time, our team will keep discussing with the designers to make sure that every details are clear. Finally, we will give our customers quotation reports.

3. Does your company provide design service?

Absolutely yes. We have helped countless customers from Europe and North American to invent their new products. Our experienced engineers give our customers useful suggestion to help them solve the problems that they encounter when designing and process the molds and products.

4. Why is your price so competitive?

First of all, what we are famous for is that we produce interchangeable core mold, which needs not only precision work but also flexible team work to adjust to what our clients really want. Also, all of our steel is from Japan and Germany and all processing steps are carried in Taiwan under the supervision of our professional engineers. We appreciate that all of our customers emphasized on quality and efficiency and that's why our company wants provide too.

To know us more please contact us with your ideas / projects / drawings, so that we can start our studying / engineering job...

To know us more, please visit

www.taiwanmoldmaker.com; www.intertech.net.tw

沒有留言:

張貼留言